Adds:Jinshan District, Shanghai

Fax:021-33250445

Emall:2638202261@qq.com 3042740069@qq.com

Product introduction

The explosion-proof chain hoist uses aluminum bronze and beryllium bronze as the blank, and the explosion-proof chain hoist shell adopts H62 copper alloy material, and the rotating gear is subjected to high-temperature heat treatment to achieve high wear resistance of the gear. In the operation, the products will not generate mechanical sparks when they collide with each other, and do not detonate the gas in the inflammable and explosive places, thus effectively preventing fire accidents.

The working principle of the explosion-proof chain hoist:

by rotating the bracelet chain, the hand wheel starts to rotate, the friction plate ratchet and the brake seat (pressed into a body) rotate together, and the five-tooth long shaft rotates the plate gear, the four-tooth short shaft and the spline Hole gear. Thus, the hoisting sprocket of the device on the spline hole gear drives the hoisting chain to smoothly lift the weight.

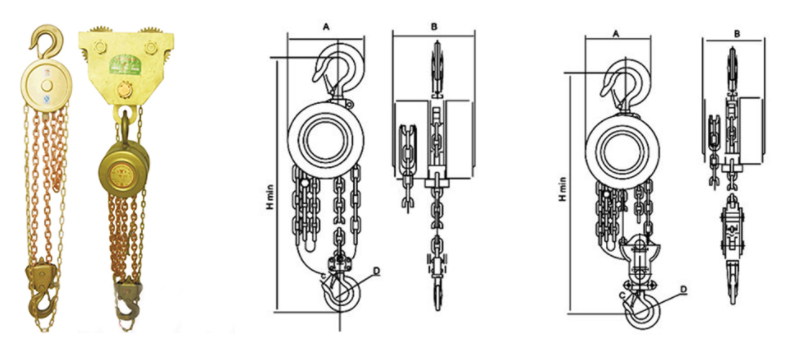

Explosion-proof chain hoist is a kind of manual lifting device that is easy to use and easy to carry. The pulling force is light and self-weight, easy to carry, beautiful in appearance, small in size and durable.

Explosion-proof chain hoists can be combined with explosion-proof manual monorail trolleys to form manual lifting transport trolleys. Explosion-proof chain hoists can be widely used in petroleum, petrochemical, petrol stations, oil depots, gas production, chemical industry, military industry, electric power, mining, electronics, railways. In the dangerous environment of potential fire and explosion, the friction between the products in the operation will cause mechanical sparks, effectively prevent fire accidents and ensure national property and personal safety. It is also a special tool essential for mechanical manufacturing and mechanical maintenance.

| model | HBSQ-1/2 | HBSQ-1 | HBSQ-1 1/2 | HBSQ-2 | HBSQ-3 | HBSQ-5 | HBSQ-10 | HBSQ-20 | |

| Lifting weight (tons) | 0.5 | 1 | 1.5 | 2 | 3 | 5 | 10 | 20 | |

| Standard lifting height (m) | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3 | 3 | |

| Test load (tons) | 0.75 | 1.5 | 2.25 | 3 | 4.5 | 7.5 | 12.5 | 25 | |

| Minimum distance between two hooks (mm) | 270 | 270 | 368 | 444 | 486 | 616 | 700 | 1000 | |

| Bracelet pull at full load (Newton) | 225 | 309 | 343 | 314 | 343 | 383 | 392 | 392 | |

| Lifting chain number | 1 | 1 | 1 | 2 | 2 | 2 | 4 | 8 | |

| Lifting chain round steel diameter (mm) | 6 | 6 | 8 | 6 | 8 | 10 | 10 | 10 | |

| Main size (mm) | A | 120 | 142 | 178 | 142 | 178 | 210 | 358 | 580 |

| B | 108 | 122 | 139 | 122 | 139 | 162 | 162 | 189 | |

| C | twenty four | 28 | 34 | 34 | 38 | 48 | 64 | 82 | |

| D | 120 | 142 | 178 | 142 | 178 | 210 | 210 | 210 | |

| Net weight (kg) | 9.5 | 10 | 16 | 14 | twenty four | 36 | 68 | 155 | |

| Packing gross weight (kg) | 12 | 13 | 20 | 17 | 28 | 45 | 83 | 193 | |

| Packing size (length x width x height) cm | 28X21X17 | 30X24X18 | 34X29X20 | 33X25X19 | 38X30X20 | 45X35X24 | 62X50X28 | 70X46X75 | |

|

Increase in weight (kg) for every 1 m increase in lifting height |

1.7 | 1.7 | 2.3 | 2.5 | 3.7 | 5.3 | 9.7 |

19.4 |

|

Product advantage

Relying on first-class technical team and advanced scientific management, the company's expansion in sales, the products not only sell well in 28 provinces, has established good business relationships with customers both at home and abroad, are welcome, also gradually formed a combined business trade, production, supply, sales, service one-stop business model, to provide users with convenient services all the way, and with high quality product quality wins high praise from all walks of life.

Service Process

High safety

automation

World brand

EU certification

Low failure rate

Shanghai Hugong Hoisting Machinery Co., Ltd. is a professional manufacturer of electric hoists, chain hoists, lever hoists, monorail trolleys, jacks, tanks and other small lifting tools and lifting machinery. The companys headquarters is located in Jinshan, Shanghai. The developed economy, convenient transportation and effective resource allocation make the company have the advantages of time, location and people.

Shanghai Hugong Hoisting Machinery Co., Ltd. is a professional manufacturer of electric hoists, chain hoists, lever hoists, monorail trolleys, jacks, tanks and other small lifting tools and lifting machinery. The companys headquarters is located in Jinshan, Shanghai. The developed economy, convenient transportation and effective resource allocation make the company have the advantages of time, location and people.