Adds:Jinshan District, Shanghai

Fax:021-33250445

Emall:2638202261@qq.com 3042740069@qq.com

Product introduction

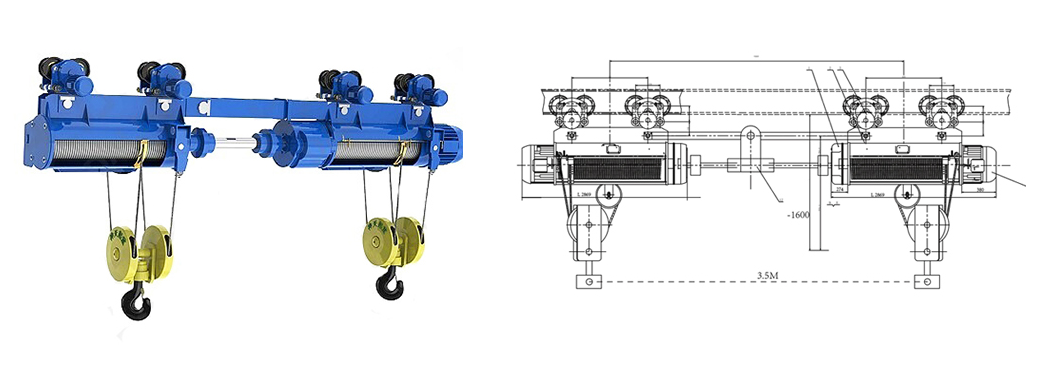

Double ropes | double hanging point electric hoist detail

double hanging point electric hoist also known as: double hook electric hoist, same as the same drop electric hoist, synchronous shaft electric hoist, one-piece double hook electric hoist, double hook electric hoist, double hook synchronization Wire rope electric hoist, double hook synchronous electric hoist, gate electric hoist, etc. The coaxial double-hook two-speed electric hoist is the two-speed hoist connected by the drive shaft as a two-speed wire rope electric hoist.

Double lifting point electric hoist Details:

Double lifting point electric hoist is suitable for lifting long workpieces or items. The hook distance can be designed according to the user's requirements. The two upper hoists are connected by an intermediate drive shaft to achieve the same lifting and lowering. When the wire rope electric hoist is lifted and lowered, the rope will be wrapped or lowered along the rope groove on the reel, and the double hook will simultaneously move to the side while rising and descending. The greater the vertical height of the object to be hung from the mounting position of the hoist, the smaller the amplitude of the translation. For example, the object to be hung is on the ground, and the hoist is installed at a height of 12 meters above the ground. When the hook is raised to the highest limit, it is 11 meters from the ground. Use a gourd with a height of 12 meters to hang objects on the ground. When the height is 6 meters, the horizontal movement is small. That is, the mounting position of the hoist is set to be a few meters above the target position of the object to be lifted. The larger the distance, the smaller the horizontal movement.

The equipment is synchronized by mechanical and electrical, and the speed of the motor is forced to synchronize. The two electric hoists use an electrical control system to overcome the electrical operation error, thus ensuring that the two electric hoists lift and lift heavy objects at the same time. The device combination is convenient, and auxiliary functions such as overload limit, height display and remote control can be added.

Coaxial double hook two-speed electric hoist:

two hoists connected by a drive shaft are two-speed wire rope electric hoist. Suitable for lifting long workpieces or items. The hook distance can be designed according to the user's requirements. Double hook wire rope electric hoist is a customized product, please call the company if you need to negotiate specific parameters.

Lifting weight: 2*10T, 2*16T, 2*32T lifting height: H=6M-24M hook distance: 1.2M≤L≤7M

The two upper hoists are connected by an intermediate drive shaft to achieve the same lifting and lowering. When the wire rope electric hoist is lifted and lowered, the rope will be wrapped or lowered along the rope groove on the reel, and the double hook will simultaneously move to the side while rising and descending. The greater the vertical height of the object to be hung from the mounting position of the hoist, the smaller the amplitude of the translation. For example, the object to be hung is on the ground, and the hoist is installed at a height of 12 meters above the ground. When the hook is raised to the highest limit, it is 11 meters from the ground. Use a gourd with a height of 12 meters to hang objects on the ground. When the height is 6 meters, the horizontal movement is small. That is, the mounting position of the hoist is set to be a few meters above the target position of the object to be lifted. The larger the distance, the smaller the horizontal movement.

| ZMCD, ZMMD series electric hoist technical performance and dimensions parameters (0.25T-20T) | |||||||||||||||||||||||||||

| model | ZMCD1 ZMMD1 | ||||||||||||||||||||||||||

| Lifting capacity | Ton | 0.25 | 0.5 | 1 | 2 | 3 | |||||||||||||||||||||

| Lifting height | Meter | 3 | 6 | 9 | 6 | 9 | 12 | 6 | 9 | 12 | 18 | twenty four | 30 | 6 | 9 | 12 | 18 | twenty four | 30 | 6 | 9 | 12 | 18 | twenty four | 30 | ||

| Lifting speed | Meter/min | 8 | 8/0.8 | 8/0.8 | 8/0.8 | 8/0.8 | |||||||||||||||||||||

| Running speed | Meter/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | |||||||||||||||||||||

| Wire rope | Rope diameter | Millimeter | 3.6 | 4.8 | 7.4 | 11 | 13 | ||||||||||||||||||||

| Wire diameter | Millimeter | 0.22 | 0.34 | 0.5 | 0.6 | ||||||||||||||||||||||

| structure type | 6×9 | D-6×37+1 | D-6×37+1 | D-6×37+1 | D-6×37+1 | ||||||||||||||||||||||

| I-beam track type (GB76-88) | 16-22b | 16-28b | 16-28b | 20a-32c | 20a-32c | ||||||||||||||||||||||

| Minimum radius of circular orbit | Meter | 0.8 | 1.5 | 1.5 | 2 | 3 | 4 | 2 | 2.5 | 3 | 4 | 2 | 2.5 | 3 | 4 | ||||||||||||

| Lifting motor | model | ZD12-4 | ZD21-4 | ZD21-4 | ZD31-4 | ZD41-4 | |||||||||||||||||||||

| capacity | kilowatt | 0.4 | 0.8 0.2/0.8 | ||||||||||||||||||||||||

| Rotating speed | Transfer / minute | 1380 | 1380 | 1380 | 1380 | 1380 | |||||||||||||||||||||

| Phase | 3 | 3 | 3 | 3 | 3 | ||||||||||||||||||||||

| Voltage | Volt | 380 | 380 | 380 | 380 | 380 | |||||||||||||||||||||

| Current | ampere | 1.25 | 2.4 0.72/2.4 | 4.3 0.72/4.3 | 7.6 1.25/7.6 | 11 2.4/11 | |||||||||||||||||||||

| frequency | Week/second | 50 | 50 | 50 | 50 | 50 | |||||||||||||||||||||

| Running motor | model | DW5024 | ZDY11-4 | ZDY12-4 | ZD12-4 | ZDY21-4 | |||||||||||||||||||||

| capacity | kilowatt | 0.06 | 0.2 | 0.2 | 0.4 | 0.4 | |||||||||||||||||||||

| Rotating speed | Transfer / minute | 1400 | 1380 | 1380 | 1380 | 1380 | |||||||||||||||||||||

| Phase | 3 | 3 | 3 | 3 | 3 | ||||||||||||||||||||||

| Voltage | Volt | 380 | 380 | 380 | 380 | 380 | |||||||||||||||||||||

| Current | ampere | 0.3 | 0.72 | 0.72 | 1.25 | 1.25 | |||||||||||||||||||||

| frequency | Week/second | 50 | 50 | 50 | 50 | 50 | |||||||||||||||||||||

| Work type and organization level | Intermediate M3 | Intermediate M3 | Intermediate M3 | Intermediate M3 | Intermediate M3 | ||||||||||||||||||||||

| Basic size ± 2% | H | Milli | 432 | 630 | 670 | 685 | 780 | 860 | 960 | 985 | 1080 | ||||||||||||||||

| L2 | Meter | 216 | 126 | 159 | 187 | 230 | |||||||||||||||||||||

| L1 | 175 | 228/225 | 269/266 | 279 | 341/343 | ||||||||||||||||||||||

| L | C | 391 | 616 | 688 | 760 | 758 | 856 | 955 | 1150 | 1346 | 1542 | 820 | 920 | 1020 | 1220 | 1420 | 1620 | 915 | 1018 | 1121 | 1327 | 1533 | 1738 | ||||

| M | 638 | 710 | 782 | 780 | 878 | 976 | 1172 | 1368 | 1564 | ||||||||||||||||||

| m | 104 | 318 | 390 | 462 | 400 | 499 | 597 | 793 | 989 | 1185 | 418 | 518 | 618 | 818 | 1018 | 1218 | 448 | 551 | 654 | 860 | 1066 | 1272 | |||||

| n | 130 | 190 | 196 | 240 | 264 | ||||||||||||||||||||||

| h | 120 | 124 | 155 | 173 | |||||||||||||||||||||||

| Φ | 16.5 | 16.5 | 19 | 25 | 25 | ||||||||||||||||||||||

| B | 279-315 | -884 | -884 | -930 | -930 | ||||||||||||||||||||||

| E | 395 | 490 | 584 | 740 | 848 | ||||||||||||||||||||||

| F | 355/426 | 354/492 | 400/562 | 438/642 | |||||||||||||||||||||||

| Total ±15% | C | public | 44 | 44.4 | 44.8 | 120 | 125 | 145 | 145 | 158 | 180 | 195 | 208 | 222 | 235 | 248 | 296 | 320 | 340 | 360 | 280 | 300 | 350 | 380 | 405 | 435 | |

| M | jin | 135 | 140 | 160 | 160 | 170 | 200 | 210 | 220 | 230 | 265 | 278 | 326 | 350 | 370 | 310 | 310 | 330 | 380 | 410 | 435 | 465 | |||||

| C solid | 30 | 30.4 | 30.8 | 80 | 85 | 90 | 120 | 120 | 125 | 140 | 150 | 165 | 168 | 180 | 190 | 210 | 230 | 250 | 220 | 235 | 250 | 275 | 300 | 325 | |||

| M solid | 100 | 105 | 110 | 130 | 140 | 145 | 155 | 165 | 180 | 196 | 210 | 220 | 240 | 260 | 280 | 250 | 265 | 280 | 305 | 330 | 355 | ||||||

| ZMCD, ZMMD series electric hoist technical performance and dimensions parameters (0.25T-20T) | |||||||||||||||||||||||||||

| model | ZMCD1 | ZMMD1 | ZMCD | NH20-12D | |||||||||||||||||||||||

| Lifting capacity | Ton | 5 | 10 | 16 | 20 | 20 | 3 | ||||||||||||||||||||

| Lifting height | Meter | 6 | 9 | 12 | 18 | twenty four | 30 | 9 | 12 | 18 | twenty four | 30 | 6 | 9 | 12 | 18 | twenty four | 30 | 6 | 9 | 12 | 18 | twenty four | 30 | |||

| Lifting speed | Meter/min | 8/0.8 | 7/0.7 | 3.5 3.5/0.35 | 3.5 3.5/0.35 | 5 | 8/0.8 | ||||||||||||||||||||

| Running speed | Meter/min | 20(30) | 20(30) | 18 | 20 | 20 | 20(30) | ||||||||||||||||||||

| Wire rope | Rope diameter | Millimeter | 15 | 15 | 15 | 17 | 22.5 | 13 | |||||||||||||||||||

| Wire diameter | Millimeter | 0.7 | 0.7 | 0.7 | 0.8 | 0.6 | |||||||||||||||||||||

| structure type | D-6×37+1 | D-6×37+1 | D-6×37+1 | D-6×37+1 | D-6×37+1 | D-6×37+1 | |||||||||||||||||||||

| I-beam track type (GB76-88) | 25a-63c | 25a-63c | 45a-63c | 50a-63c | 20a-32c | ||||||||||||||||||||||

| Minimum radius of circular orbit | Meter | 2.5 | 3 | 4 | 5 | 2.5 | 3.5 | 4 | 6 | 9 | 3 | 3.5 | 4.6 | 3 | 3.5 | 4.6 | 2 | 2.5 | 3 | 4 | |||||||

| Lifting motor | model | ZD41-4 | ZD51-4 | ZD51-4 | ZD51-4 | ZD41-4 | |||||||||||||||||||||

| capacity | kilowatt | ||||||||||||||||||||||||||

| Rotating speed | Transfer / minute | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | ||||||||||||||||||||

| Phase | 3 | 3 | 3 | 3 | 3 | 3 | |||||||||||||||||||||

| Voltage | Volt | 380 | 380 | 380 | 380 | 380 | 380 | ||||||||||||||||||||

| Current | ampere | 18 2.4/18 | 30 4.3/30 | 30 4.3/30 | 30 4.3/30 | 11 2.4/11 | |||||||||||||||||||||

| frequency | Week/second | 50 | 50 | 50 | 50 | 50 | 50 | ||||||||||||||||||||

| Running motor | model | ZDY21-4 | ZDY21-4 | ZDY21-4 | ZDY21-4 | ZDY21-4 | |||||||||||||||||||||

| capacity | kilowatt | 0.8 | 0.8×2 | 0.8×2 | 0.8×2 | 0.8×2 | 0.4 | ||||||||||||||||||||

| Rotating speed | Transfer / minute | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | ||||||||||||||||||||

| Phase | 3 | 3 | 3 | 3 | 3 | 3 | |||||||||||||||||||||

| Voltage | Volt | 380 | 380 | 380 | 380 | 380 | 380 | ||||||||||||||||||||

| Current | ampere | 2.4 | 2.4×2 | 2.4×2 | 2.4×2 | 2.4×2 | 1.25 | ||||||||||||||||||||

| frequency | Week/second | 50 | 50 | 50 | 50 | 50 | 50 | ||||||||||||||||||||

| Work type and organization level | Intermediate M3 | Intermediate M3 | Intermediate M2 | Intermediate M2 | Intermediate M3 | ||||||||||||||||||||||

| Basic size ± 2% | H | Milli | 1160 | 1310 | 1350 | 1600 | 2400 | 985 | 1080 | ||||||||||||||||||

| L2 | Meter | 274 | 303 | Same as 10t | 230 | ||||||||||||||||||||||

| L1 | 380/377 | 429/820 | Same as 10t | 341/343 | |||||||||||||||||||||||

| L | C | 1047 | 1157 | 1257 | 1467 | 1677 | 1887 | 1602 | 1783 | 2145 | 2507 | 1869 | Same as 10t | 915 | 1018 | 1121 | 1327 | 1533 | 1738 | ||||||||

| M | 1059 | 1169 | 1269 | 1479 | 1682 | 1899 | 1969 | 2150 | 2512 | 2874 | 3236 | ||||||||||||||||

| m | 485 | 606 | 695 | 860 | 1115 | 1325 | 949 | 1130 | 1492 | 1854 | 2216 | 949 | 1130 | 1492 | 956 | 1478 | 1605 | 448 | 551 | 654 | 860 | 1066 | 1272 | ||||

| n | 320 | 376 | 376 | 376 | 264 | ||||||||||||||||||||||

| h | 203 | 243 | 41 | 46 | 173 | ||||||||||||||||||||||

| Φ | 31 | 37 | 25 | ||||||||||||||||||||||||

| B | -1058 | -1058 | -930 | ||||||||||||||||||||||||

| E | 998 | 1068 | 1335 | 1934 | 848 | ||||||||||||||||||||||

| F | 472/675 | 612 | 1055 | 438/642 | |||||||||||||||||||||||

| Total ±15% | C | public | 445 | 470 | 555 | 590 | 630 | 670 | 1010 | 1063 | 1166 | 1263 | 1317 | 280 | 300 | 350 | 380 | 405 | 435 | ||||||||

| M | jin | 480 | 505 | 590 | 630 | 660 | 705 | 1100 | 1153 | 1256 | 1353 | 1407 | 310 | 330 | 380 | 410 | 435 | 465 | |||||||||

| C solid | 355 | 375 | 390 | 425 | 460 | 500 | 759 | 807 | 900 | 987 | 1032 | 220 | 235 | 250 | 275 | 300 | 325 | ||||||||||

| M solid | 390 | 410 | 425 | 460 | 500 | 535 | 849 | 897 | 990 | 1077 | 1122 | 250 | 265 | 280 | 305 | 330 |

355 |

||||||||||

Product advantage

Relying on first-class technical team and advanced scientific management, the company's expansion in sales, the products not only sell well in 28 provinces, has established good business relationships with customers both at home and abroad, are welcome, also gradually formed a combined business trade, production, supply, sales, service one-stop business model, to provide users with convenient services all the way, and with high quality product quality wins high praise from all walks of life.

Service Process

High safety

automation

World brand

EU certification

Low failure rate

Shanghai Hugong Hoisting Machinery Co., Ltd. is a professional manufacturer of electric hoists, chain hoists, lever hoists, monorail trolleys, jacks, tanks and other small lifting tools and lifting machinery. The companys headquarters is located in Jinshan, Shanghai. The developed economy, convenient transportation and effective resource allocation make the company have the advantages of time, location and people.

Shanghai Hugong Hoisting Machinery Co., Ltd. is a professional manufacturer of electric hoists, chain hoists, lever hoists, monorail trolleys, jacks, tanks and other small lifting tools and lifting machinery. The companys headquarters is located in Jinshan, Shanghai. The developed economy, convenient transportation and effective resource allocation make the company have the advantages of time, location and people.