Adds:Jinshan District, Shanghai

Fax:021-33250445

Emall:2638202261@qq.com 3042740069@qq.com

Product introduction

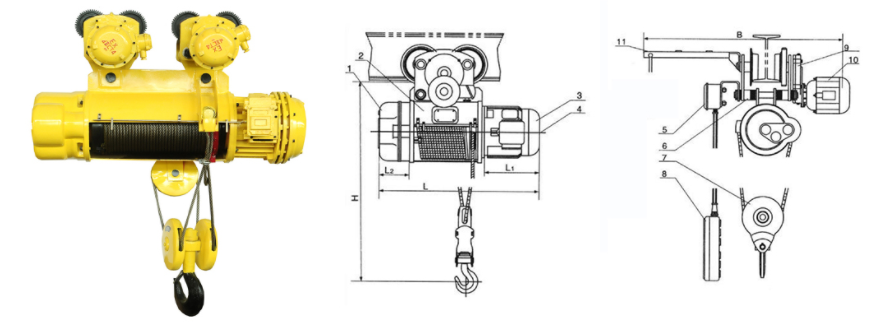

HB, HBS. BHC. BCD type explosion-proof electric hoist is a series of products.

The explosion-proof motor and explosion-proof electrical appliances used in this product, whether designed or manufactured by our factory or produced by the supporting factory, are all in accordance with national standard GB3836. 1-2000 "Electrical Equipment for Explosive Gas Environments: General Requirements", GB3836.2-2000 <Electrical Equipment for Explosive Gas Environments: Explosion-proof Type "D"*", etc. Designated, manufactured and accepted, and designated by the state The inspection unit of the China National Explosion-proof Electrical Products Testing Center Nanyang Sub-center has reviewed and tested the well test for qualified factory explosion-proof lifting equipment.

This product must be used in strict accordance with the conditions specified in the Manual.

Scope of application

1. Explosion-proof electric hoist is a series of products, designed and manufactured according to GB3836.1-2000 "Electrical equipment for explosion-proof gas environment: general requirements".

2. This series of three-stage explosion-proof electric hoist is suitable for the explosive mixture formed by the flammable gas, steam and air specified in Table 1 in the factory; this series of four-stage electric hoist is suitable for the flammability specified in Table 1 in the factory. When an explosive mixture of gas, swallow gas and air is formed; it is mounted on the I-shaped steel rail to lift heavy objects, and can reciprocate along the track in a straight line and curve to ensure sufficient safety.

3. This series of products has compact structure, light weight, small volume and large lifting capacity. When the factory is filled with explosive mixture, it is a favorable tool to improve working conditions and improve labor productivity under the premise of ensuring safety, thus becoming a reasonable process. The necessary mechanical equipment.

4. Use environment: temperature -20C-+40C altitude below 1000M relative humidity 85% (20 soil 5C)

5. In series products can be used according to different use requirements, with LXB type explosion-proof single-beam suspension crane or LB, LHB type explosion-proof single Double girder bridge cranes are used together.

| Explosion-proof grade | Temperature level | |||

| T1 | T2 | T3 | T4 | |

| d11A |

Ethane, propane, styrene, xylene, carbon monoxide, acetone acetic acid, methyl acetate, ammonia, pyridine |

Ethanol, butane, propylene, ethyl acetate, dioxane ethane, ethylene chloride alkenyl, thiophene ring to an alcohol, dichloroethane, dimethylamine |

Alkanes, decane, ethyl naphthenes, turpentine, naphtha, petroleum (including automobile oil, fuel oil) alcohol, chlorobutane, tetrahydrothiophene |

Ether, acetaldehyde, trimethylamine |

| d11B | Propane, acrylonitrile, hydrogen cyanide, coke oven gas | Ethylene, cyclopropylethane, acrylic acid, methyl ester, furan | Dimethyl ether, acrolein, tetrahydrofuran, hydrogen sulfide | |

| Natural temperature level | T1 | T2 | T3 | T4 |

| d11A |

Ethane, propane, acetone, styrene chloride, chloro benzene, toluene, ammonia, carbon dioxide, acetic acid, ethyl acetate |

Ethanol, butane, propylene, butane acetate, acetic acid , acid, naphthenic, butanol |

Alkane, heptane, octane, decane, gasoline | Ethanol |

| d11B | Propyne, acrylonitrile | Oxyethane, butadiene, butene | Hydrogen sulfide, dimethyl ether | Diethyl ether, dibutyl ether |

| d11C | Hydrogen, water gas | Acetylene | ||

| Note: Technical performance table parameters refer to BCD, BMD | ||||

| BCD, BMD series electric hoist technical performance and shape parameters (0.25T-20T) | |||||||||||||||||||||||||||

| model | BCD1 BMD1 | ||||||||||||||||||||||||||

| Lifting capacity | Ton | 0.25 | 0.5 | 1 | 2 | 3 | |||||||||||||||||||||

| Lifting height | Meter | 3 | 6 | 9 | 6 | 9 | 12 | 6 | 9 | 12 | 18 | twenty four | 30 | 6 | 9 | 12 | 18 | twenty four | 30 | 6 | 9 | 12 | 18 | twenty four | 30 | ||

| Lifting speed | Meter/min | 8 | 8/0.8 | 8/0.8 | 8/0.8 | 8/0.8 | |||||||||||||||||||||

| Running speed | Meter/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | |||||||||||||||||||||

| Wire rope | Rope diameter | Millimeter | 3.6 | 4.8 | 7.4 | 11 | 13 | ||||||||||||||||||||

| Wire diameter | Millimeter | 0.22 | 0.34 | 0.5 | 0.6 | ||||||||||||||||||||||

| structure type | 6×9 | D-6×37+1 | D-6×37+1 | D-6×37+1 | D-6×37+1 | ||||||||||||||||||||||

| I-beam track type (GB76-88) | 16-22b | 16-28b | 16-28b | 20a-32c | 20a-32c | ||||||||||||||||||||||

| Minimum radius of circular orbit | Meter | 0.8 | 1.5 | 1.5 | 2 | 3 | 4 | 2 | 2.5 | 3 | 4 | 2 | 2.5 | 3 | 4 | ||||||||||||

| Lifting motor | model | ZD12-4 | ZD21-4 | ZD21-4 | ZD31-4 | ZD41-4 | |||||||||||||||||||||

| capacity | kilowatt | 0.4 | 0.8 0.2/0.8 | ||||||||||||||||||||||||

| Rotating speed | Transfer / minute | 1380 | 1380 | 1380 | 1380 | 1380 | |||||||||||||||||||||

| Phase | 3 | 3 | 3 | 3 | 3 | ||||||||||||||||||||||

| Voltage | Volt | 380 | 380 | 380 | 380 | 380 | |||||||||||||||||||||

| Current | ampere | 1.25 | 2.4 0.72/2.4 | 4.3 0.72/4.3 | 7.6 1.25/7.6 | 11 2.4/11 | |||||||||||||||||||||

| frequency | Week/second | 50 | 50 | 50 | 50 | 50 | |||||||||||||||||||||

| Running motor | model | DW5024 | ZDY11-4 | ZDY12-4 | ZD12-4 | ZDY21-4 | |||||||||||||||||||||

| capacity | kilowatt | 0.06 | 0.2 | 0.2 | 0.4 | 0.4 | |||||||||||||||||||||

| Rotating speed | Transfer / minute | 1400 | 1380 | 1380 | 1380 | 1380 | |||||||||||||||||||||

| Phase | 3 | 3 | 3 | 3 | 3 | ||||||||||||||||||||||

| Voltage | Volt | 380 | 380 | 380 | 380 | 380 | |||||||||||||||||||||

| Current | ampere | 0.3 | 0.72 | 0.72 | 1.25 | 1.25 | |||||||||||||||||||||

| frequency | Week/second | 50 | 50 | 50 | 50 | 50 | |||||||||||||||||||||

| Work type and organization level | Intermediate M3 | Intermediate M3 | Intermediate M3 | Intermediate M3 | Intermediate M3 | ||||||||||||||||||||||

| Basic size ± 2% | H | Milli | 432 | 630 | 670 | 685 | 780 | 860 | 960 | 985 | 1080 | ||||||||||||||||

| L2 | Meter | 216 | 126 | 159 | 187 | 230 | |||||||||||||||||||||

| L1 | 175 | 228/225 | 269/266 | 279 | 341/343 | ||||||||||||||||||||||

| L | C | 391 | 616 | 688 | 760 | 758 | 856 | 955 | 1150 | 1346 | 1542 | 820 | 920 | 1020 | 1220 | 1420 | 1620 | 915 | 1018 | 1121 | 1327 | 1533 | 1738 | ||||

| M | 638 | 710 | 782 | 780 | 878 | 976 | 1172 | 1368 | 1564 | ||||||||||||||||||

| m | 104 | 318 | 390 | 462 | 400 | 499 | 597 | 793 | 989 | 1185 | 418 | 518 | 618 | 818 | 1018 | 1218 | 448 | 551 | 654 | 860 | 1066 | 1272 | |||||

| n | 130 | 190 | 196 | 240 | 264 | ||||||||||||||||||||||

| h | 120 | 124 | 155 | 173 | |||||||||||||||||||||||

| Φ | 16.5 | 16.5 | 19 | 25 | 25 | ||||||||||||||||||||||

| B | 279-315 | -884 | -884 | -930 | -930 | ||||||||||||||||||||||

| E | 395 | 490 | 584 | 740 | 848 | ||||||||||||||||||||||

| F | 355/426 | 354/492 | 400/562 | 438/642 | |||||||||||||||||||||||

| Total ±15% | C | public | 44 | 44.4 | 44.8 | 120 | 125 | 145 | 145 | 158 | 180 | 195 | 208 | 222 | 235 | 248 | 296 | 320 | 340 | 360 | 280 | 300 | 350 | 380 | 405 | 435 | |

| M | jin | 135 | 140 | 160 | 160 | 170 | 200 | 210 | 220 | 230 | 265 | 278 | 326 | 350 | 370 | 310 | 310 | 330 | 380 | 410 | 435 | 465 | |||||

| C solid | 30 | 30.4 | 30.8 | 80 | 85 | 90 | 120 | 120 | 125 | 140 | 150 | 165 | 168 | 180 | 190 | 210 | 230 | 250 | 220 | 235 | 250 | 275 | 300 | 325 | |||

| M solid | 100 | 105 | 110 | 130 | 140 | 145 | 155 | 165 | 180 | 196 | 210 | 220 | 240 | 260 | 280 | 250 | 265 | 280 | 305 | 330 | 355 | ||||||

| BCD, BMD series electric hoist technical performance and shape parameters (0.25T-20T) | |||||||||||||||||||||||||||

| model | BCD1 | BMD1 | BCD | NH20-12D | |||||||||||||||||||||||

| Lifting capacity | Ton | 5 | 10 | 16 | 20 | 20 | 3 | ||||||||||||||||||||

| Lifting height | Meter | 6 | 9 | 12 | 18 | twenty four | 30 | 9 | 12 | 18 | twenty four | 30 | 6 | 9 | 12 | 18 | twenty four | 30 | 6 | 9 | 12 | 18 | twenty four | 30 | |||

| Lifting speed | Meter/min | 8/0.8 | 7/0.7 | 3.5 3.5/0.35 | 3.5 3.5/0.35 | 5 | 8/0.8 | ||||||||||||||||||||

| Running speed | Meter/min | 20(30) | 20(30) | 18 | 20 | 20 | 20(30) | ||||||||||||||||||||

| Wire rope | Rope diameter | Millimeter | 15 | 15 | 15 | 17 | 22.5 | 13 | |||||||||||||||||||

| Wire diameter | Millimeter | 0.7 | 0.7 | 0.7 | 0.8 | 0.6 | |||||||||||||||||||||

| structure type | D-6×37+1 | D-6×37+1 | D-6×37+1 | D-6×37+1 | D-6×37+1 | D-6×37+1 | |||||||||||||||||||||

| I-beam track type (GB76-88) | 25a-63c | 25a-63c | 45a-63c | 50a-63c | 20a-32c | ||||||||||||||||||||||

| Minimum radius of circular orbit | Meter | 2.5 | 3 | 4 | 5 | 2.5 | 3.5 | 4 | 6 | 9 | 3 | 3.5 | 4.6 | 3 | 3.5 | 4.6 | 2 | 2.5 | 3 | 4 | |||||||

| Lifting motor | model | ZD41-4 | ZD51-4 | ZD51-4 | ZD51-4 | ZD41-4 | |||||||||||||||||||||

| capacity | kilowatt | ||||||||||||||||||||||||||

| Rotating speed | Transfer / minute | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | ||||||||||||||||||||

| Phase | 3 | 3 | 3 | 3 | 3 | 3 | |||||||||||||||||||||

| Voltage | Volt | 380 | 380 | 380 | 380 | 380 | 380 | ||||||||||||||||||||

| Current | ampere | 18 2.4/18 | 30 4.3/30 | 30 4.3/30 | 30 4.3/30 | 11 2.4/11 | |||||||||||||||||||||

| frequency | Week/second | 50 | 50 | 50 | 50 | 50 | 50 | ||||||||||||||||||||

| Running motor | model | ZDY21-4 | ZDY21-4 | ZDY21-4 | ZDY21-4 | ZDY21-4 | |||||||||||||||||||||

| capacity | kilowatt | 0.8 | 0.8×2 | 0.8×2 | 0.8×2 | 0.8×2 | 0.4 | ||||||||||||||||||||

| Rotating speed | Transfer / minute | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | ||||||||||||||||||||

| Phase | 3 | 3 | 3 | 3 | 3 | 3 | |||||||||||||||||||||

| Voltage | Volt | 380 | 380 | 380 | 380 | 380 | 380 | ||||||||||||||||||||

| Current | ampere | 2.4 | 2.4×2 | 2.4×2 | 2.4×2 | 2.4×2 | 1.25 | ||||||||||||||||||||

| frequency | Week/second | 50 | 50 | 50 | 50 | 50 | 50 | ||||||||||||||||||||

| Work type and organization level | Intermediate M3 | Intermediate M3 | Intermediate M2 | Intermediate M2 | Intermediate M3 | ||||||||||||||||||||||

| Basic size ± 2% | H | Milli | 1160 | 1310 | 1350 | 1600 | 2400 | 985 | 1080 | ||||||||||||||||||

| L2 | Meter | 274 | 303 | Same as 10t | 230 | ||||||||||||||||||||||

| L1 | 380/377 | 429/820 | Same as 10t | 341/343 | |||||||||||||||||||||||

| L | C | 1047 | 1157 | 1257 | 1467 | 1677 | 1887 | 1602 | 1783 | 2145 | 2507 | 1869 | Same as 10t | 915 | 1018 | 1121 | 1327 | 1533 | 1738 | ||||||||

| M | 1059 | 1169 | 1269 | 1479 | 1682 | 1899 | 1969 | 2150 | 2512 | 2874 | 3236 | ||||||||||||||||

| m | 485 | 606 | 695 | 860 | 1115 | 1325 | 949 | 1130 | 1492 | 1854 | 2216 | 949 | 1130 | 1492 | 956 | 1478 | 1605 | 448 | 551 | 654 | 860 | 1066 | 1272 | ||||

| n | 320 | 376 | 376 | 376 | 264 | ||||||||||||||||||||||

| h | 203 | 243 | 41 | 46 | 173 | ||||||||||||||||||||||

| Φ | 31 | 37 | 25 | ||||||||||||||||||||||||

| B | -1058 | -1058 | -930 | ||||||||||||||||||||||||

| E | 998 | 1068 | 1335 | 1934 | 848 | ||||||||||||||||||||||

| F | 472/675 | 612 | 1055 | 438/642 | |||||||||||||||||||||||

| Total ±15% | C | public | 445 | 470 | 555 | 590 | 630 | 670 | 1010 | 1063 | 1166 | 1263 | 1317 | 280 | 300 | 350 | 380 | 405 | 435 | ||||||||

| M | jin | 480 | 505 | 590 | 630 | 660 | 705 | 1100 | 1153 | 1256 | 1353 | 1407 | 310 | 330 | 380 | 410 | 435 | 465 | |||||||||

| C solid | 355 | 375 | 390 | 425 | 460 | 500 | 759 | 807 | 900 | 987 | 1032 | 220 | 235 | 250 | 275 | 300 | 325 | ||||||||||

| M solid | 390 | 410 | 425 | 460 | 500 | 535 | 849 | 897 | 990 | 1077 | 1122 | 250 | 265 | 280 | 305 | 330 |

355 |

||||||||||

Product advantage

Relying on first-class technical team and advanced scientific management, the company's expansion in sales, the products not only sell well in 28 provinces, has established good business relationships with customers both at home and abroad, are welcome, also gradually formed a combined business trade, production, supply, sales, service one-stop business model, to provide users with convenient services all the way, and with high quality product quality wins high praise from all walks of life.

Service Process

High safety

automation

World brand

EU certification

Low failure rate

Shanghai Hugong Hoisting Machinery Co., Ltd. is a professional manufacturer of electric hoists, chain hoists, lever hoists, monorail trolleys, jacks, tanks and other small lifting tools and lifting machinery. The companys headquarters is located in Jinshan, Shanghai. The developed economy, convenient transportation and effective resource allocation make the company have the advantages of time, location and people.

Shanghai Hugong Hoisting Machinery Co., Ltd. is a professional manufacturer of electric hoists, chain hoists, lever hoists, monorail trolleys, jacks, tanks and other small lifting tools and lifting machinery. The companys headquarters is located in Jinshan, Shanghai. The developed economy, convenient transportation and effective resource allocation make the company have the advantages of time, location and people.